Project Location: Carlton House – NSW

Client: Watpac

Project Duration: 2015-2018

Scope of Contracting Works:

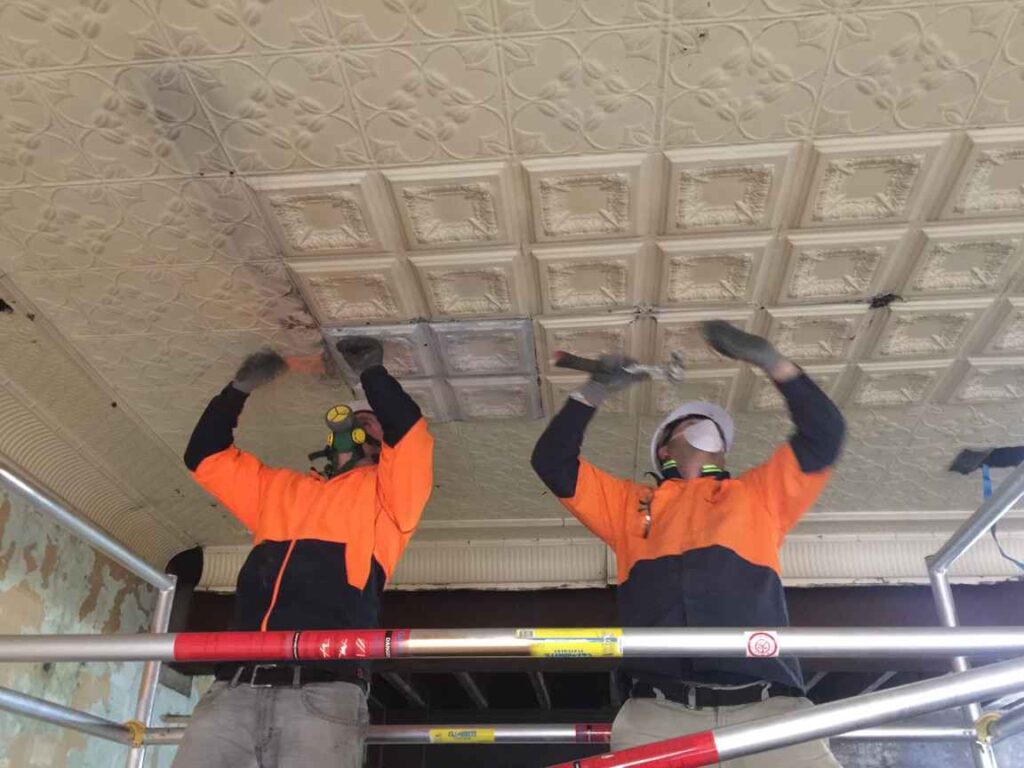

Restoration, removal and reinstallation of original pressed metal panels over multiple floors. Installation of new pressed metal panels like for like and creation of York Street Panels to recreate original ceiling rose. Preservation of original historic features as per Heritage Architect instructions.

Project Description:

Extensive repair and restoration works were carried out on Carlton House situated on York and George Streets in Chippendale Sydney, by National Pressed Metal, contracting arm of the Australian Pressed Metal Group. Teams from Sydney Pressed Metal and Adelaide Pressed Metal worked closely with builder Watpac and Heritage Architects to work on the restoration of the pressed metal ceilings in Carlton House. Extensive restoration, removal and replacement works were carried out over mutiple levels to restore the original pressed metal where possible by the skilled teams.

In areas that required complete replacement Australian Pressed Metal panels were used, manufactured in imperial measurements from superior grade aluminium to the highest specifications fitting in seamlessly with the repairs of the original pressed metal ceilings where the panels were too damaged to restore. Most of the original designs were already in production keeping costs to a minimum. Only two new dies were needed, manufactured by the experienced team to create the magnificent centre ceiling rose now named York Street in homage to one of the streets Carlton House is located on. Other designs used throughout the restoration are; Magnolia, Canning, Dana, Queen of Hearts, Stockholm, St John conices, beam cladding and Aztec batten.

The extensive project included removal and reinstallation of original pressd metal and installation of new pressed metal 6 bays deep and 3 bays across over multiple levels with a different design on each level. Original pressed metal was removed from the back 4 bays and reinstalled in the front 2 bays with new pressed metal installed in the back 4 bays to allow for alterations to comply with current building codes. Specialised work was carried out to Heritage Architects request when the original goods lift shaft was discovered on each level. To preserve the original area and create a heritage timeline, recycled original pressed metal was used in this area, framed up using the exact same rail pattern and border frieze to indicate where the original goods lift was installed.